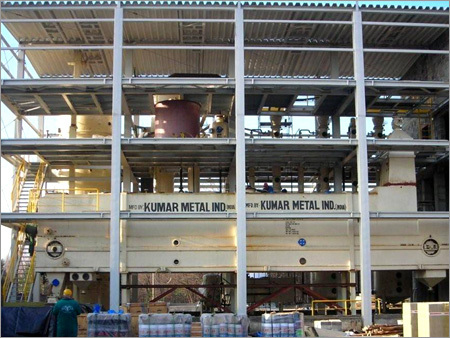

Industrial Solvent Extraction Plant

Product Details:

Industrial Solvent Extraction Plant Price And Quantity

- 1 Set

Industrial Solvent Extraction Plant Trade Information

- Cash on Delivery (COD) Cash Advance (CA) Delivery Point (DP) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Western Union Paypal Cash Against Delivery (CAD) Telegraphic Transfer (T/T) Days after Acceptance (DA) Cash in Advance (CID) Cheque

- Australia Eastern Europe Western Europe Africa Asia

Product Description

We manufacture and export the Solvent Extraction Plant that is completely intended for large and medium scale processing. Through these plants the users get pure solvent by applying de-solventizer techniques. All these plants are precisely engineered by utilizing quality certified components sourced after a keen research of market vendors. Moreover, our respected clients can easily acquire the Solvent Extraction Plant according to their specified specifications and time limits.

Features:

- Long operational life

- Impeccable functionality

- Robustly designed

Our range of solvent Extraction Plant includes :

100 TPD - 500 TPD with Cake/Rice Bran/Sunflower Preparatory

Technicalities-

Drive

Kumar Extractor is a powerful, performance oriented machine, which consists of an individual piece gear box which is affixed onto the main jibe of the device. This positioning helps in avoiding the use of big gears, which reduces the maintenance costs by a phenomenal level. Running on cutting edge technology, the motor which this equipment uses operates via the VFD(variable frequency drive), which enables one to control the speed of the machinery as per processing rates. Not only this, but the VFD also pays a pivotal role when it comes to data logging such as run time, stoppage, history etc.

Built

The Kumar Extractor is a beast when it comes to construction parameters. The individual miscella hopper which has zero weld joints helps in bringing down any chance of leakages while the equipment is operating. In order to make our product line a 100 percent resistant to corrosion, we use a sandblasting and finishing technique which consists of a zinc-based epoxy formulation, right before the fabrication process begins. This also acts as a positive point, since it multiplies the life expectancy of the machinery by many folds.

Our machinery are produced in the in-house factories held by us. Before any product leaves manufacturing division, we run constant tests on them so as to make sure that each patron receives nothing but a faultless operating device. The prefabrication process carried out by us trims down the erection and commissioning time. The bed height is selected in such a manner that it brings down any possibilities of miscella channeling.

The advantages of low bed height

- The mark feeding pace to DT is continual at all times. This in fact is a boon for the machines as it aids in easy and steady vapour flow, along with the control over the loss of hexane.

- Since the weight per square metre is lesser in comparison to the other version of extractors(true-deep extractors in specific), which guarantees low depreciation of a band conveyor. Thus, due to this reason, the loading of such machine beds are generally kept low.

The advantages of additional two hoppers

- Not just one, but two! The additional miscella hopper, which is placed at the discharge ending allows a higher degree of hexane drainage before being released onto the DT. This reduces the load on the DT, thus guaranteeing a minimal steam and hexane to vaporize. This also helps majorly, in decreasing the circulation for condensation purposes as well.

- The other hopper which is present at the feed end makes it a point to see that the subsiding aspect of the miscella seeding takes place. One major advantage of the dual equipments, is that they allow major fines to get settled in a quick and efficient manner.

- Most importantly, we utilize a special miscella coating for these instruments, which allows hem to suck it the inbound flakes. This allows the miscella circulation sprays to operate in an effective and reliable manner.

Specification

| Installation Services | Yes |

| Capacity | 100 TPD - 500 TPD |

| Brand | KUMAR |

| Automation Grade | Automatic |

| Power Source | 3 Phase 50 Hz |

| Voltage | As per local requirement |

| Material | C.S./S.S. |

| Design Type | KUMAR |

| Machine Type | AUTOMATIC |

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese