Edible Oil Refinery Plant

Product Details:

Product Description

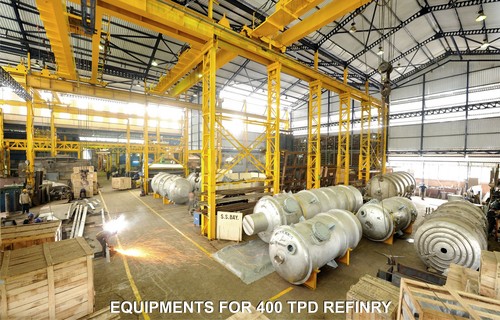

Our professionals are specialized in manufacturing and exporting the Edible Oil Refinery. These plants are wisely engineered to provide complete refinement such as bleach, pre-treat, deodorize palm olein and strip. Well equipped with all the required facilities, our plants are easy to use and operate. Widely used for deodorizing neutralized oil, the Edible Oil Refinery plant is also useful for deodorizing and striping the qualitative physical refining of FFA parts.

Features:

- Easy to maintain

- User friendly design

- Corrosion proof surface finish

Further Details:

The system is designed to fully refine, i.e. pre treat, bleach, strip and deodorize Palm olein. In the Pre Treatment section phosphoric acid is added to crude oil, which reacts with the gums present in oil. The Bleaching System is based on treatment with bleaching earth followed by filtration. The High Efficiency Deodorizing System can be used for deodorizing of neutralized oils as well as stripping and deodorizing of high FFA oils as part of physical refining.

Superior Performance

Process Economy

- Electrical Power : Systematically designed process piping manifold, heat exchangers with low pressure drops, precisely determined duty parameters and selection of high efficiency process pumps, result in lower electrical power consumption compared to conventional plant supplier.

- Steam / Heat Energy : Kumar Process is designed such that optimum heat is recovered from hot oil.

- Chemical and adsorbent : High shear mixers from reputed manufacturers ensure intimate contact of phosphoric / citric acid, hence lower acid consumption per MT of Oil. Efficient design of bleaching reactor ensure low adsorbent consumption.

Lower oil losses

- Pretreatment and Bleaching : High efficiency bleaching and reduced adsorbents result in lower loss of oil.

- Chemical Process : Our selection of Centrifugal Separators, Mixers and Heat Exchangers lead to control heating of the oil to the required temperature. Proper mixing of oil with the chemical and superior separation of gums and soap from the oil leads to lower losses.

- Deodorization : The deodorizer consists of precisely designed structured packing for low pressure drop and high surface density that ensure intimate contact of stripping steam with oil, resulting in lesser free oil entrainment with stripping steam.

- Operator friendly and easy maintenance We select superior quality hardware in our process plants. Construction of equipment is simplified for operation and maintenance. Operating as per the proceures given in the Manual will ensure low operation and maintenance costs.

- Excellent quality of output Oil. Refined oil from our refining system is in acceptance with all required parameters of the International market such as FFA, Color, Peroxide value etc.

- International Certification As per applicable international norms, equipments and machinery are manufactured in compliance with ASME and EU Directives

Our standard of quality and workmanship is based on ISO 9001-2008 standard and our company is certified by JAS ANZ Accredited by Joint Accreditation system of Australia and New Zealand since 2002

A Complete Package

Kumar is a global company. Not only do we serve customers around the world, we also use the best technology and supply resources to ensure that only the best is delivered to our customers. We have installed and commissioned several Oil Mills, Solvent Extraction Plants and Refineries around the world. Our vast experience and expertise to design and install complete process plants on turnkey basis has given us the competitive edge. We have our presence in over 30 countries and serve more than 500 clients.

Our services also include

- Installation design in compliance with international standards

- Complete process automation

- Skilled manpower for supervision of installation and commissioning

- Technical and manpower assistance to bring your new installation on line in minimum possible time.

- We provide skilled operated staff and also train the local staff.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese