Back to top

Celebrating our huge years of existence and wide knowledge by offering Pre Treatment And Bleaching Plant, Vibro Separator, Hammer Mill Machine, Distillation Plant, etc.

Kumar Metal Industries Pvt. Ltd. has been providing the oils and fats business with reliable process engineering solutions since 1939. We are renowned for our well-designed, adaptable, and operationally successful equipment and plants. Because of this, we are trusted by more than 560 clients across 74 countries to handle all of their processing needs, no matter how big or little. Over the years, we have attained specialization in manufacturing Edible Oil Refinery Plant, Oil Nuetralizer Plant, Oil Mill Machinery, Flake And Drier Cooler, Mechanical Extraction Plant and allied products.

Kumar provides creative and environmentally friendly answers to process engineering problems for the worldwide oils and fats sector. For more than 85 years, Kumar has been professionally run and proudly family-owned. We have a stake in our clients' success because of our independence, which enables us to seamlessly integrate resources, procedures, and experience to produce results that cannot be disputed. We plan and think in generations rather than quarters, and we invest in our people as well as in innovation and the future of our company so that we may all advance together.

Strategic Partners

Kumar supports strategic alliances that enable companies in our sector, regardless of location, to access state-of-the-art technology.

Our Purpose

Our goal is to provide process engineering excellence to the worldwide oils and fats industry by means of cost optimization, sustainable solutions, creative problem resolution, and operational excellence that builds relationships and fosters trust.

Our Vision

To be the most client-focused process technology and EPCC firm in the world, address customer needs via empowerment, sustainability, and innovation, and provide flawless, high-quality service while adhering to the highest professional standards.

Our Core Values

Our Glorious History

Kumar has developed over three generations to provide the oils and fats industry with innovation and superior process engineering. Technology, creativity, and the ambition to help shape the oils and fats sector are what drive us. We arrived here in this manner.

1939-

1947-

1955-

1960s-

1970s-

1980s-

2000s-

2010s-

2020s-

Our Team

The problems that our clients face are complicated, and our job is technological. In order to effectively define and distinguish Kumar's course as we advance the oils and fats processing business, our senior leadership team possesses a wide range of cross-functional experience. Get to know the group of executives guiding our business into the future.

Our Technologies

We are a strong partner for end-to-end solutions for the whole oilseed industry lifecycle, from seed preparation to post-purchase assistance, thanks to our 360-degree approach to process engineering.

The entire range of oilseed processing solutions is at your disposal because to Kumar's extensive knowledge, our technology-first strategy, and our customer-focused approach.

R&D- OM Innovation Centre

With the opening of the OM Innovation Centre at our Mumbai headquarters in honor of our founder Onkarnath Manaktala, we have made a major investment in our future. We are thrown into the global technology innovator area by this hub for technological insight, advancement, and collaboration. Emerging technologies are the focus of our team of technologists and engineers. In order to ensure that our customers worldwide receive oil and meal quality that beyond their expectations, they are entrusted with creating data-driven solutions to tackle the problems of oil extraction and refining.

Kumar's clients can use the Innovation Center to test their theories on oilseed technology and specialized oil and fat processing. Customers may model plant-processing operations to scale in a controlled setting thanks to its fully operational and extensively instrumented pilot plant, which has equipment for preparation, extraction, and refining.

Techvantage Kumar

We prioritize our customers' changing needs by designing dependable processes with the future in mind. Our solutions are made to adapt to the oil and fats industry's rapid changes by providing reliable, highly efficient, and reasonably priced systems that will help you achieve your goals for many years to come.

Value-driven Technology-

For both greenfield and brownfield projects, we provide a range of services under "one umbrella" in the oils and fats industry, including design, engineering, manufacture, construction, installation, commissioning, validation, operations, and maintenance. Our innovative approach enables us to provide better engineering, technically sound equipment, and customized, value-driven solutions.

Over 500 clients in 65 countries throughout the world have come to trust us because of our diligence, honesty, and focus on providing prompt service.

Dependable Engineering-

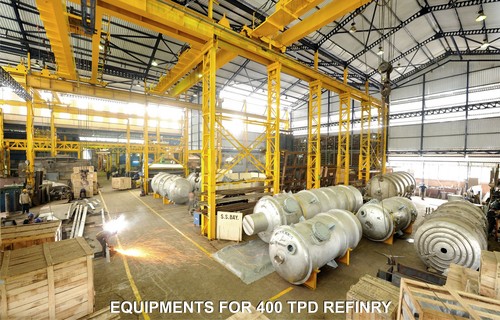

Over 400 qualified technicians, quality control staff, trained laborers, and the newest in precision European gear are housed in our manufacturing and fabrication facilities, which cover an area of more than 22,762 square meters. We are a TUV-certified ISO 9001-2015 company that produces CE-marked and ATEX-approved goods.

Our fabrication facilities are staffed by certified x-ray qualified welders and are set up to produce high-pressure vessels. Our highly skilled TIG/MIG welders take over for hard facing and essential wear and tear areas.

Kumar provides creative and environmentally friendly answers to process engineering problems for the worldwide oils and fats sector. For more than 85 years, Kumar has been professionally run and proudly family-owned. We have a stake in our clients' success because of our independence, which enables us to seamlessly integrate resources, procedures, and experience to produce results that cannot be disputed. We plan and think in generations rather than quarters, and we invest in our people as well as in innovation and the future of our company so that we may all advance together.

Strategic Partners

Kumar supports strategic alliances that enable companies in our sector, regardless of location, to access state-of-the-art technology.

- CPM

- Crown

- Arisdyne Systems

- Anderson International Group

Our Purpose

Our goal is to provide process engineering excellence to the worldwide oils and fats industry by means of cost optimization, sustainable solutions, creative problem resolution, and operational excellence that builds relationships and fosters trust.

Our Vision

To be the most client-focused process technology and EPCC firm in the world, address customer needs via empowerment, sustainability, and innovation, and provide flawless, high-quality service while adhering to the highest professional standards.

Our Core Values

- Integrity- Even when no one is looking, we try to act morally and are guided by our ethics. We are dedicated to acting in the best interests of our employees, clients, and partners, and we respect honesty and openness.

- Innovation- We are progressive thinkers who push ourselves daily to provide long-term answers to whatever problems our clients may face, no matter how minor. We search for methods to raise our standards and advance the business with each solution.

- Continuous Improvement- The heart of our business is our clientele. Through constant improvement of our processes, services, and products, we aim to meet or beyond client expectations with every encounter and take great delight in providing a seamless experience.

- Agility- In order to give our customers a competitive edge and to satisfy the quickly changing needs of our markets and consumers, we work hard to launch new product lines, upgrades, and manufacturing advancements that will cut operating costs or increase profitability for our clients.

Our Glorious History

Kumar has developed over three generations to provide the oils and fats industry with innovation and superior process engineering. Technology, creativity, and the ambition to help shape the oils and fats sector are what drive us. We arrived here in this manner.

1939-

- In Lahore, the former Punjab, Kumar Metal Industries began as a modest workshop producing spare parts for oil mill gear. The Lever Brothers, Godrej Oil Mills, and Tata Oil Mills are some of our clients.

1947-

- Our founder, Onkarnath Manaktala, leaves behind everything he laboriously constructed and travels to India with his family following the partition.

- He starts again by renting a modest workshop in the heart of Mumbai and provides replacement components for the equipment used in oil mills.

1955-

- The company begins manufacturing oil expellers.

1960s-

- Expellers were now the company's main product.

- G.K. Manaktala, the brother of our founder, establishes Kumar as an exporter by entering East African markets such as Tanzania, Uganda, and Kanya.

- In Sudan, a good friend opens doors.

1970s-

- Our Managing Director, Sunil Manaktala, enters the company a few years after our Chairman, Sudhir Manaktala, does.

- While Sunil enters South East Asia, Australia, and West Africa, Sudhir continues our expansion throughout Africa.

- In India, we sell our machines to Marico and VVD, who rely on Kumar's strong construction, meticulous engineering, and in-depth knowledge of the extraction process.

1980s-

- The business expands rapidly and invests much in equipment and warehouse space.

- In order to handle our expanding activities with more than 100 people, our company headquarters relocate to a new plant on the outskirts of Mumbai.

- The company welcomes Aditya, the first of the third generation of Manaktalas. We expand the Kumar roster by adding additional categories and goods.

2000s-

- One of the biggest producers of oil mills in the world, Kumar offers high-quality products at competitive prices and is expanding its global presence.

- To keep up with the growing demand, we moved our manufacturing activities to a large new factory on the outskirts of Mumbai.

- The company welcomes Rishab, the second of the third-generation Manaktalas.

- In order to produce and market solvent extraction plants and refineries in the Indian, African, and Asian markets, we have entered into a technical partnership with Crown Iron Works, USA.

- For a Crown customer in Brazil, we produce and install the biggest SEP manufactured by an Indian business at a rate of 4000 TPD.

2010s-

- The final third-generation employee to join the company, Akshaya Manaktala, travels overseas.

- We collaborate with Arisdyne Systems, the creators of CFC Systems, a cutting-edge but tried-and-true method for boosting oil yield in refining systems.

2020s-

- In order to produce and market Anderson Dox Extruders and Solvex Expanders in India, we have entered into a manufacturing license with Anderson International Corp, USA, a 130-year-old leader in the vegetable/oilseed extraction sector and a pioneer of expeller press technology.

- On our headquarters site, we established the Onkarnath Manaktala Innovation Centre to work with our technology partners and clients to find answers to the important problems facing our sector now and in the future.

- The Biju As CEO, George Palayil assumes a leadership position to spearhead the subsequent stage of international growth.

- Kumar defines success at every stage, from a small workshop in south Mumbai to expansive, highly technologically equipped plants and a global presence across the oil and fats industries' process engineering domain.

Our Team

The problems that our clients face are complicated, and our job is technological. In order to effectively define and distinguish Kumar's course as we advance the oils and fats processing business, our senior leadership team possesses a wide range of cross-functional experience. Get to know the group of executives guiding our business into the future.

- Mr. Sudhir Manaktala, Chairman

- Mr. Biju George Palayil, Chief Executive Officer

- Mr. Clive Musson, President, Business Development

- Mr. Aditya Manaktala, Executive Director - Admin & HR

- Mr. Rishabh Manaktala, Executive Director - Strategy & Growth

- Mr. Akshaya Manaktala, Executive Director - Innovation & Product Development

Our Technologies

We are a strong partner for end-to-end solutions for the whole oilseed industry lifecycle, from seed preparation to post-purchase assistance, thanks to our 360-degree approach to process engineering.

The entire range of oilseed processing solutions is at your disposal because to Kumar's extensive knowledge, our technology-first strategy, and our customer-focused approach.

- Oilseed Preparation

- Oilseed Extraction

- Oil Refining

- Specialty Processes

- Filtration & Conveying

- Fat Modification

- Value Added Products

- Feed Mills

- Biodiesels

- Oleochemicals

R&D- OM Innovation Centre

With the opening of the OM Innovation Centre at our Mumbai headquarters in honor of our founder Onkarnath Manaktala, we have made a major investment in our future. We are thrown into the global technology innovator area by this hub for technological insight, advancement, and collaboration. Emerging technologies are the focus of our team of technologists and engineers. In order to ensure that our customers worldwide receive oil and meal quality that beyond their expectations, they are entrusted with creating data-driven solutions to tackle the problems of oil extraction and refining.

Kumar's clients can use the Innovation Center to test their theories on oilseed technology and specialized oil and fat processing. Customers may model plant-processing operations to scale in a controlled setting thanks to its fully operational and extensively instrumented pilot plant, which has equipment for preparation, extraction, and refining.

Techvantage Kumar

We prioritize our customers' changing needs by designing dependable processes with the future in mind. Our solutions are made to adapt to the oil and fats industry's rapid changes by providing reliable, highly efficient, and reasonably priced systems that will help you achieve your goals for many years to come.

Value-driven Technology-

For both greenfield and brownfield projects, we provide a range of services under "one umbrella" in the oils and fats industry, including design, engineering, manufacture, construction, installation, commissioning, validation, operations, and maintenance. Our innovative approach enables us to provide better engineering, technically sound equipment, and customized, value-driven solutions.

Over 500 clients in 65 countries throughout the world have come to trust us because of our diligence, honesty, and focus on providing prompt service.

Dependable Engineering-

Over 400 qualified technicians, quality control staff, trained laborers, and the newest in precision European gear are housed in our manufacturing and fabrication facilities, which cover an area of more than 22,762 square meters. We are a TUV-certified ISO 9001-2015 company that produces CE-marked and ATEX-approved goods.

Our fabrication facilities are staffed by certified x-ray qualified welders and are set up to produce high-pressure vessels. Our highly skilled TIG/MIG welders take over for hard facing and essential wear and tear areas.

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese